Efficiency, sustainability and conservation are all topics that must be considered in today’s business regardless of the industry. At the core of many businesses utility operations are cooling requirements that call for the use of a cooling tower. If allowed to operate in an uncontrolled environment, the water and energy efficiencies in cooling towers can be costly. Furthermore, an uncontrolled cooling tower puts the asset at risk for high repair costs and risks downtime for production operations.

The size, investment, and operational costs of a cooling tower vary greatly depending on the heat load. One thing is for certain, for any business the cooling tower is a significant source of capital and operational expenditures. Increases in water and energy costs, as well as regulation water conservation efforts, requires that the bar be raised when it comes to water treatment programs for cooling towers. California began water conservation efforts state wide that requires a 20% reduction in per capita water use by 2020 (20×2020). U.S. Water recently completed a project for a hospital in California to not only help meet these requirements by saving 3.6 MM gallons of water per year, but also saves them $76,000 per year in operational costs.

A cooling tower water treatment program is in place to prevent scaling, biological growth, and corrosion. The type of treatment required depends on the water quality that feeds the tower. Cooling towers, by their nature will evaporate a certain amount of water causing the impurities in the water to concentrate or cycle up. Increasing the cycles concentration in a cooling tower will conserve water. There is a limit on the number of cycles that can be run while balancing the water chemistry to prevent scaling, corrosion, and biological activity.

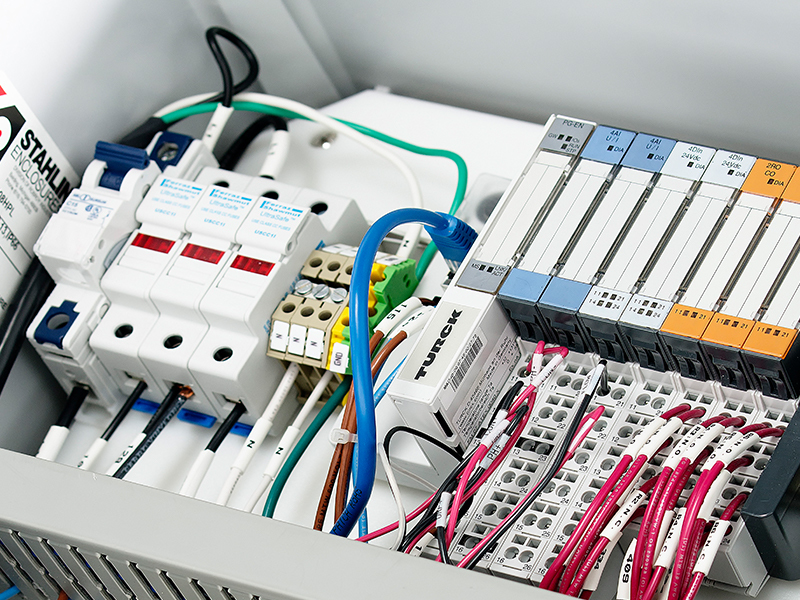

There are a number of methods to treat the water chemistry in a cooling tower. No matter whether the treatment method is a chemical or mechanical means or a combination of both of these, there are conditions that need to be monitored and controlled. One such method is the use of industrial control and automation systems. Cooling tower controllers will monitor the tower basin water for a number of conditions and provide feedback to the treatment method being used to react to the changing conditions. Generally speaking, there are a few main sensing technologies that are widely used in cooling tower water chemistry monitoring. New technologies such as monitoring a trace component added to the water treatment chemicals have provided enhanced sensing methods.

Historically, cooling tower operations demanded significant manpower; in some cases requiring testing 3-4 times per shift. Reductions in manpower for most industries have demanded more reliable sensors and new sensing technologies. But more importantly, this has pushed the industry to develop methods of monitoring the controllers remotely and notifying on developing conditions.

There are a wide range of cooling tower controllers available on the market today. Almost all of these controllers have some sort of communications capability. Remote communications to provide notifications and a remote portal by which to view the conditions of the controller has become an industry standard in cooling tower automation. Operators and water treaters can set limits on the parameters being monitored in the controller and have email or text message notifications sent to them in the case of excursions. A remote portal allows a user to “log in” to a controller to view the latest readings and in some cases, view trends of the parameters being monitored. These communication enhancements have enabled businesses to essentially have 24 hour coverage of their cooling tower operations.

In the case of the California hospital mentioned earlier, U.S. Water combined what would normally be considered an aggressive treatment program with an industrial automation and control program featuring advanced communication technologies to provide significant water treatment and operational cost savings to the customer. With remote communication capabilities, U.S. Water’s remote monitoring service desk reviews the water treatment operations on a daily basis and provides weekly performance reports. Additionally, if any component of the operation falters during off hours, notifications are sent. Response protocols ensure that a qualified engineer examines the situation and reacts accordingly.

When choosing a cooling tower controller, care should be taken to examine the sensing options that are available. Also consider the replacement procedure and expandability. Be sure that the controller has the communication specifications that your operation requires. Communication methodology is not consistent among controllers. Be sure to discuss the communication requirements of the controller with your IT department prior to purchase.