Kurita has defined products, technologies, or business models that contribute significantly to reducing CO2 emissions, water and energy use, and waste for society and the customer. The Kurita Group strives to create shared value (CSV) with society by providing optimal solutions that maximize the use of management resources to address various issues facing society. To this end, we maintain high sensitivity to social issues while working to improve our competence base as a company and provide comprehensive water treatment solutions.

Kurita is driven to research and develop new technologies that meet customers’ needs, aiming for the further evolution of water treatment products. Our technologies and expertise can lower your operating costs, increase your plant productivity, and optimize the safety of your employees and your facilities.

Kurita provides unique value demanded by customers and aims to create shared value with the society.

Society

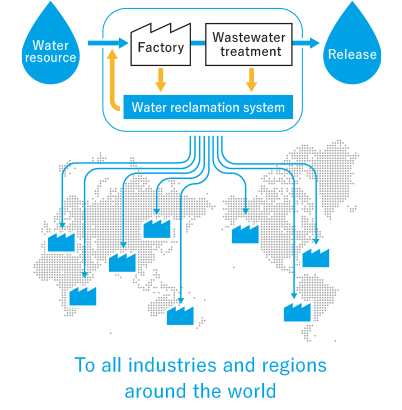

SocietyWater shortages have become a serious problem all over the world. Kurita has created technologies for utilizing water with maximum efficiency. We will realize effective utilization of water resources by widely applying our technologies for saving, purifying, and reusing water to secure the water necessary for the development of lives and industries.

Customer

Kurita has developed a new wastewater reuse system, incorporating cutting-edge technologies and expertise in both chemicals and facilities. We developed this system to realize a good balance between water resource supply and demand by reusing water for regions and customers facing shortages.

Society

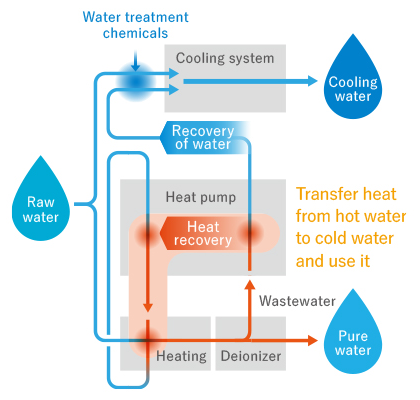

SocietyEnergy demand has been expanding with the ongoing increase in the global population, accompanied by an increase in CO2 emissions. Efficient and optimized energy use has gained prominent attention.

Customer

A factory consumes a vast amount for making steam, hot water, and cold water in addition to using water chemicals to improve the heat efficiency of factory equipment, such as boilers, cooling tower, and manufacturing equipment. Since its foundation, Kurita has been providing products and technologies that contribute to improving the energy efficiency of boilers and various other facilities.

Society

Society

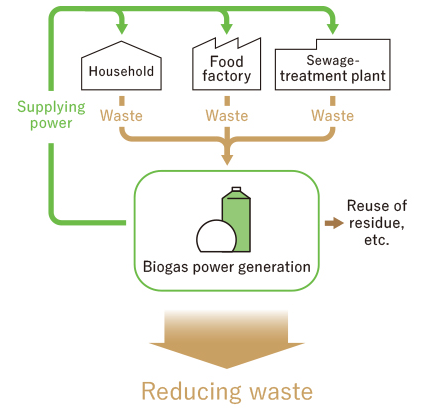

Waste generated daily has an impact on the global environment, including pollution and the destruction of ecosystems. Solving these issues will require initiatives for reducing waste and facilitating the recycling of resources. Kurita aims to create a system for reducing waste and reusing it into resources in a community-wide manner.

Customer

Kurita has been talking steps to reduce waste generated in a factory's wastewater treatment process, thus reusing it in other technologies, such as biological treatment. We will continue to provide solutions for realizing zero waste together with our customers and local communities.

Society

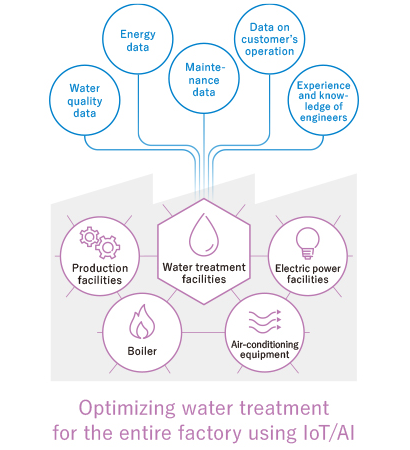

SocietyIn a smart factory, the internet of things (IoT) is used for improving productivity and quality, making effective use of resources and energy, and other purposes. Kurita aims to use the data not only for water treatment facilities but also for efficiency improvement and stable operation of the entire factory.

Customer

Kurita will seek to optimize water treatment in the entire factory by making full use of the internet of things (IoT) and artificial intelligence (AI) by converting our many years of experience and expertise in water treatment, water quality, facility maintenance history, and status of energy use into digital data.

Creating Shared Value Solutions

Below you will find a list of Kurita Global's Shared Value products, as well as Kurita America's Shared Value Products, PhosZero and EnergyOUT .

Cetamine®

Kurita’s innovative Cetamine technology is designed for complete protection of steam generators, hot water boilers, and closed systems as well as corrosion protection in open cooling systems. Composed of film-forming amines (FFA), Cetamine creates a hydrophobic protective film. This film, adsorbed on all metal surfaces in the system, creates a continuous barrier between water and metal, effectively inhibiting corrosion without affecting the heat transfer.

Learn MoreDReeM Polymer™

Kurita's DReeM Polymer is a unique chemistry developed to maximize heat transfer surface cleanliness and efficiency, and minimize fuel costs in low to medium pressure boilers. This award winning technology is unparalleled as an on-line cleaner of silica and iron silicate boiler deposits, and has won multiple energy conservation awards, named the most effective silica dispersant available for high temperature applications.

Learn MoreDropwise Condensation Technology

Kurita’s Dropwise Condensation Technology is designed to increase operating efficiency, improve productivity, and conserve energy in industrial production facilities. Dropwise is dosed continuously into the steam line in front of the target heat exchanger, creating a water-repellent film on the heat transfer surfaces.

Learn MoreEnergyOUT™

Often, plants are looking to increase their steam boiler efficiency but do not have a sufficient capital budget for a new Reverse Osmosis (RO) system. Kurita America's fully integrated EnergyOUT solution meets this need. Available through an operating lease, EnergyOUT includes equipment, standard service, chemicals, and consumables for a set, monthly price.

Learn More about this Kurita America ProductKuriverter® IK-110

Kurita's patented Kuriverter IK-110 is a unique chemistry developed to maximize operational efficiency and normalized flow through reverse osmosis membrane systems. This proprietary biological control agent specifically targets biofilm, encouraging it to release from surfaces into the bulk water, where it can be flushed from the system. Kuriverter IK-110 applications have been proven to decrease pressure drop across filters, increase normalized flow back to near new condition on the RO, stabilize salt rejection, and reduce operation and energy costs.

Learn MorepHytOUT®

Developed specifically for the biofuels industry, Kurita's patented pHytOUT technology is a liquid deposit control inhibitor that is typically added to the fermenters. This easy to feed chemistry can reduce an ethanol plants dependency upon sulfuric acid while providing an overall process fouling inhibitor package.

Learn MoreS.sensing® CS

Kurita’s S.sensing CS system is an automatic, chemical injection monitoring system to control coagulant for optimum results. The S.sensing CS system ensures correct dosage of treatment, reduced labor costs and sludge disposal, consistent effluent quality, reduced surcharges and more!

Learn MoreSimul-Wash™

Kurita America’s Simul-Wash backwash system provides optimal cleaning of media filters while minimizing water waste. Central to the process is our innovative trough design, which prevents media loss during combined air/water backwash without restricting flow, allowing for sustained cleaning durations to realize the greatest value.

Learn MoreKurita’s Water and Environment Event™

Exploring Sustainable Solutions to Optimize Your Facility