Understanding the key considerations for boiler lay-up and the differences between wet and dry procedures helps safeguard the boiler and ensure a smooth restart. Treating lay-ups as part of a broader maintenance strategy, rather than an afterthought, can prevent costly repairs and extend system life. Before choosing a lay-up method, it is important to review system design, water quality, and operational needs to ensure the procedure provides adequate protection.

Why Boiler Lay-Up Matters

With more steam boilers being used intermittently, there is renewed focus on properly treating and protecting boiler systems while they are offline.

In many industries that rely on steam generation — including power production, manufacturing, food processing, chemical plants, and other industrial operations — it is increasingly common for boilers to operate intermittently rather than continuously. Power generation facilities, for example, may run less than 30% of the time, while industrial plants often have seasonal or variable production demands that leave boilers idle for extended periods. As renewable energy sources, such as wind and solar shift, grid dynamics, and as industrial facilities fluctuate between production cycles, boilers are placed in and out of service more frequently. This increased cycling makes planned boiler lay-ups essential for maintaining equipment reliability, preventing corrosion, and ensuring safe startup when the boiler is returned to service. During these idle periods, plant operators must balance asset protection with business realities.

A proper boiler lay-up, whether wet or dry, is a critical part of boiler maintenance, reducing the risk of corrosion, scale, and costly damage.

What Is a Boiler Lay-Up?

A boiler lay-up refers to the process of preparing and maintaining a boiler that is temporarily removed from service. Lay-up procedures are designed to prevent internal corrosion, preserve system integrity, and ensure that the boiler can be safely restarted when needed.Lay-ups are generally classified as short-term or long-term depending on how long the boiler will remain out of operation. Short-term layups often involve maintaining water in the system (wet lay-up), while long-term shutdowns typically require removing all water and drying the boiler internal surfaces (dry lay-up). Choosing the proper lay-up procedure depends on several factors, including the expected downtime, climate, and system design.

When Should You Use Wet vs. Dry Lay-up?

Wet and dry lay-ups each serve a unique purpose. Wet lay-ups are typically recommended for short-term boiler shutdowns, like seasonal or intermittent operations, while dry lay-ups are preferred for long-term storage or summer shutdown periods. The main goal of either method is to prevent corrosion by controlling oxygen exposure and moister levels inside the boiler.Selecting the appropriate method ensures the boiler remains protected against corrosion while allowing a quick and efficient restart.

Wet Boiler Lay-up Procedure

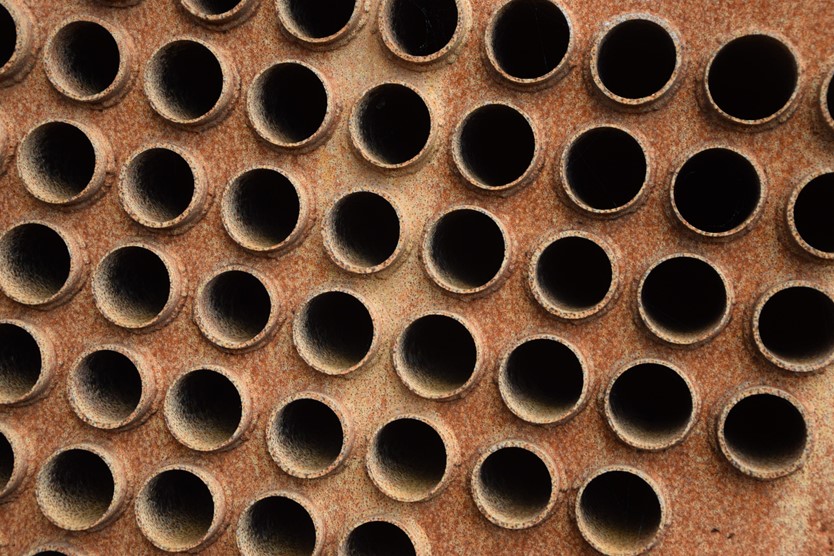

The goal of a wet boiler lay-up is to keep internal surfaces submerged in chemically treated water to prevent oxygen and acidic corrosion. Maintaining proper boiler water chemistry during shutdown helps preserve the protective magnetite layer on steel surfaces and prevents oxygen pitting upon restart.

Step-by-Step Wet Lay-up Process:

- Fill the boiler completely with treated feedwater to the normal operating level.

- Elevate the internal pH to between 10.5 and 11.5 before shutdown.

- Circulate the boiler water to prevent pH stratification.

- Increase oxygen scavenger residual to 3 times normal operation level

- Maintain slight positive pressure (3-5 psi) to prevent air infiltration.

- Periodically monitor water chemistry to ensure consistent protection.

Hot lay-up keeps the boiler warm and under positive pressure using residual heat, a heating coil, or cascading blowdown from another boiler. This limits oxygen solubility and prevents air from entering the system. Alternatively, cold lay-up uses nitrogen gas blanketing to maintain positive pressure (3-5 psi) when heat is not available. In both cases, an oxygen scavenger should be added to remove dissolved oxygen remaining in the boiler water.

In a cascading blowdown setup, blowdown from an adjacent, operational, or auxiliary boiler is directed into the offline boiler through the lower header, or mud drum, to promote natural circulation. The effectiveness of this method depends on the size and output of the operating boiler. In some cases, the available blowdown flow may not provide enough heat to maintain positive pressure throughout the lay-up process. Cascading blowdown can speed off-line boiler restart but requires careful attention to maintain water quality parameters.

Using a heating coil, either steam or electric, is another highly effective method of hot lay-up, offering better control and alleviating some concerns with cascading blowdown. Hot lay-up is generally preferred when practical as it reduces thermal stress on boiler components and maintains natural circulation. If the system will be offline for an extended period or a heat source is not available, cold lay-up with nitrogen blanketing provides an effective alternative.

Regardless of method, continuous monitoring of pH, dissolved oxygen, and pressure are necessary to maintain optimal boiler water conditions.

Dry Boiler Lay-Up Procedure

The preferred choice for long-term boiler storage is dry lay-up. Dry lay-up completely removes water from the boiler, preventing corrosion from moisture and oxygen. This method is especially useful for seasonal shutdowns or systems that will remain offline for several months.

Step-by-Step Dry Lay-Up Process

- Drain the boiler while it is still warm and under slight pressure (25-50 psi) to promote drying of internal surfaces once drained.

- Ensure all low points and dead legs are fully drained.

- Install desiccants or circulate dehumidified air to keep the internal environment dry.

- Seal the system to prevent humid air from entering.

- Inspect and replace desiccant materials as needed according to manufacturer’s recommendations.

The goal is to keep metal surfaces above the ambient dew point and isolated from air and humidity. Stack dampers or temporary seals can also prevent moisture ingress on the fireside of the boiler.

Common Mistakes to Avoid

Even a well-intentioned lay-up program can fail if key steps are overlooked. Common mistakes include

- Neglecting to clean the boiler internally before beginning the lay-up.

- Using untreated or improperly treated water.

- Failing to monitor pH or oxygen levels during lay-up.

- Failure to maintain nitrogen blanket pressure on the boiler.

- Restarting using unsoftened, untreated feedwater or not testing boiler water quality.

Final Recommendations

Whether your operation calls for a short-term wet lay-up or a long-term dry lay-up, careful planning and attention to detail are essential. When properly executed, both methods significantly reduce corrosion risk and help maintain boiler performance over time.Clear documentation, routine inspections, and consistent monitoring help ensure the lay-up remains effective and support a smoother transition between shutdown and start-up. Approaching lay-ups as a defined phase of boiler operation further protects critical assets, minimizes downtime risks, and maintains reliable performance year-round.

To optimize your boiler system, contact Kurita.