While clean-in-place (CIP) systems are often overlooked or underappreciated for optimal plant operations, they save time, labor, and expenses by maintaining efficient operations without disassembly. Failed or inadequate CIP can lead to loss of heat transfer, increased energy costs, increased bacterial infections, equipment damage, and lost profits. Biofuels plants should prioritize optimizing CIP as an investment in regulatory compliance, production efficiency, and overall product quality. Current CIP practices have room for improvements, to ensure peak performance, including changes in chemistries and bacteria control, overall facility cleanliness, and hygiene audit.

CIP Practices

The four Ts of CIP allows plants to have the greatest impact on the effectiveness of their CIP process.

- Temperature is vital for bacterial control. Make sure at least 170°F is reached during a CIP event to ensure a good bacterial kill.

- Turbulence, also known as agitation or mechanical action, increases cleaning and makes the system chemistry more effective. Flow rate of the CIP solution should be as high as possible to get the best turbulence for optimal cleaning action. The higher the flow rate the greater the turbulence in the line and the better the cleaning

- Titration and choosing the right chemistry for the soil type is vital. Using the wrong chemistry at too low of dosage can lead to failed CIP or require longer cleaning times.

- Time can be the most valuable resource, optimize the other Ts so time is used most effectively. Make sure that exposure times of each chemistry used in the CIP program reaches or exceeds SOP requirements.

Of the four Ts, changing product strength or chemistry are the easiest ways to optimize CIP performance. An informed choice of CIP chemistries can help shape a well-run CIP program.

CIP Chemistries

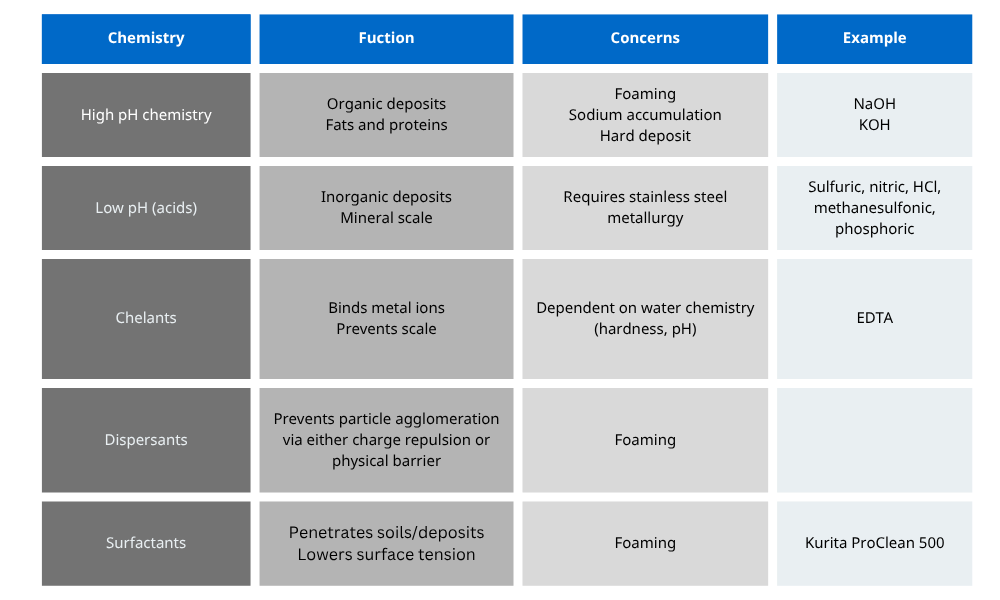

Choosing the correct CIP chemistry can greatly impact plant performance. Plants should understand what soil or deposit is building up in their equipment as this will impact the chemistry choice. Deposits — including proteins, fiber, starch/sugars, phytate, carbonates, oxalates, magnesium phosphate, and many others — can build up throughout the plant. Each of these deposits will respond to different CIP chemistries with varying success.

Selecting the right chemistry for each identified soil type will lead to optimal CIP performance.

Bacterial Control

Bacterial infections during fermentation can have expensive consequences, such as up to 22% ethanol yield losses. Insufficient CIP of yeast propagators, fermenters, headers, and mash exchangers can lead to deposit build-up, such as biofilm and beerstone, which supports persistent infections. Responsible use of antibiotics is important to help combat bacterial infections.

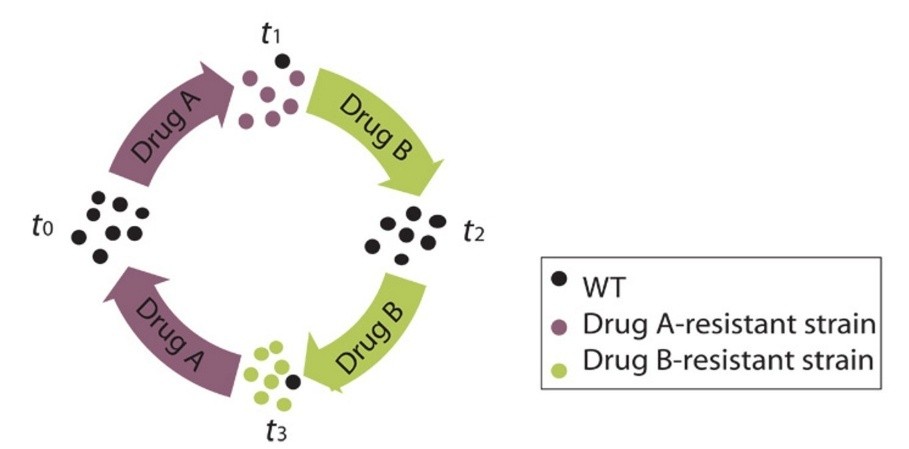

Kurita highly recommends rotating between different antibiotic modes of action to prevent or reduce development of antibiotic resistance, ensuring the available antibiotics will remain effective. If resistance does develop or antibiotics are not an option, antibiotic-free treatments (chlorine dioxide, hydrogen peroxide and/or peroxyacetic acid) are available. Kurita also offers an iodine/surfactant blend ProClean 253 as a post-CIP rinse aid for fermentation to help boost infection control.

Of course, these solutions alone will not stop an infection from returning, which is why facilities need routine preventative maintenance protocols and overall cleanliness to stay on top of any possible outbreaks.

Imamovic, L. & Sommer, M.O.A. (2013) Use of collateral sensitivity networks to design drug cycling protocols that avoid resistance development. 5:204

Pal, C., Papp, B., & Lazar, V. (2015) Collateral sensitivity of antibiotic-resistant microbes. 23(7): 401-407

Facility Cleanliness and Maintenance

Cleanliness of all areas in the plant will improve performance and profitability, but some areas in the plant might be routinely overlooked, such as cooling towers and dust control. Successful cooling water management allows the plant to best utilize water resources.

Additionally, air quality and dust control can pose a breathing risk for personnel and an explosion or fire risk. Dust can accumulate on various surfaces in the plant such as the bag house, thermal oxidizers, stack economizers, induced draft fans, and ductwork near dried distillers grains (DDGs) storage. For example, dust build-up on stack economizers can lead to increased energy costs due to reduced heat transfer. Removal of dust not only improves safety but also saves energy costs.

Plant cleanliness and maintenance should be made a priority for safety, cost savings, and plant performance.

CIP Improvements

No matter the process, improvements can always be made to increase performance. As the CIP solution circulates, it often accumulates debris in the form of solids. Maintaining and monitoring CIP screens that are often part of the CIP system will remove unwanted particles. These unwanted particles can reduce the overall efficacy of the CIP solution.

Automation is one of the most effective enhancements to the CIP process for its consistent and accurate control over CIP chemistries and temperatures, allowing for optimization and potential cost reductions. These improvements can be identified during hygiene audits.

Hygiene Audits

As periodic evaluations of the CIP processes and the overall plant operations, hygiene audits are an invaluable tool to ensure a plant’s CIP process is effective. Hygiene audits are conducted by a team of plant personnel from varying departments to examine CIP process performance and identify possible improvements. Remember, equipment should be re-calibrated during audits to ensure proper operation.

Kurita can help you with your hygiene audits as well as overall provide technical expertise and chemicals to help your facility run efficiently. These audits pinpoint issues, decrease operational downtime, ensure preventative maintenance completion, and maintain overall cleanliness of the plant.

It is important to consider that each plant is unique, so the CIP program should evolve with changes to plant operations to ensure peak performance. Optimizing CIP programs protects equipment, promotes a safe work environment, prevents unnecessary downtime, and saves chemical and energy costs leading to increased profits for ethanol plants.

Please reach out to Kurita to help optimize your CIP performance.