For media filters, the phrase “if it ain’t broke, don’t fix it” often prevents necessary, routine maintenance from occurring. Due to budget constraints and competing priorities, refurbishing your filter may be the last thing on your mind, especially when it is still removing contaminants below regulatory standards. However, waiting too long can result in lost efficiency or decreased performance, and it could turn a routine maintenance project into a costly emergency. In this article, we will explore some recommended practices and scope considerations for refurbishing media filters to prevent these undesired situations.

Media filtration is a reliable and robust water treatment technology employed widely to remove a number of contaminants from water, such as iron, manganese, arsenic, radium, turbidity, and general suspended solids. These systems are costly capital investments and critical infrastructure for protecting public health. Along with good operating practices, routine maintenance is paramount to ensure reliable and consistent performance while maximizing the usable equipment life. This includes periodic filter refurbishments, the scope of which often varies depending on equipment age.

The primary reason to refurbish a media filter is to replace the media, and this is recommended once every 10 to 20 years. Over time, media changes in size and property, which affects contaminant removal performance, the rate of increasing head loss, and the appropriate backwash frequency. Media grains break down through repeated use as small pieces fracture off and then exit the filter during backwash. This phenomenon is generally called “attrition,” and it is not unusual to lose up to one inch of media depth per year. Alternatively, media grains can grow in size from fouling and coating as a result of water chemistry. This alters the average media particle density and affects stratification during backwash. Media can also agglomerate into clumps or “mudballs” to cause uneven flow distribution and lessen the filter’s capacity for removing solids (see Figure 1).

Fortunately, none of this happens overnight, and there is considerable flexibility when fitting this important maintenance event into an asset management plan. For planning purposes, 15 years is a good rule of thumb to replace media. Though, the optimal time depends on many factors like operation frequency, backwash frequency, and backwashing methods. Media does not simply stop working; rather, as the media’s properties change over time, so will the filter’s performance and efficiency. For example, you may start seeing breakthrough at the end of a filter run and compensate by increasing the backwash frequency, or you may notice that head loss is building more quickly, again requiring more frequent backwashing. In both cases, let us assume that the filter is still removing contaminants immediately following a backwash; however, the need to backwash more frequently is using more water. The filter may be working, but it is not working efficiently.

Slow, gradual loss in performance can easily go unnoticed and possibly work against a proactive asset management plan. However, the longer a filter operates with the original media, the more its media will diverge from the original specification. If replacing media beyond the expected life, then the new media can be quite different than the used media being replaced. In this case, the filter may perform differently after the refurbishment, even if the new media matches the original specification of the existing media. Core samples can be collected for analysis to assess a media’s condition, but obtaining a representative sample can be tricky as can separating a dual media for individual analysis. As best practice, Kurita America recommends replacing filter media as indicated above to ensure consistent filter performance throughout its life cycle.

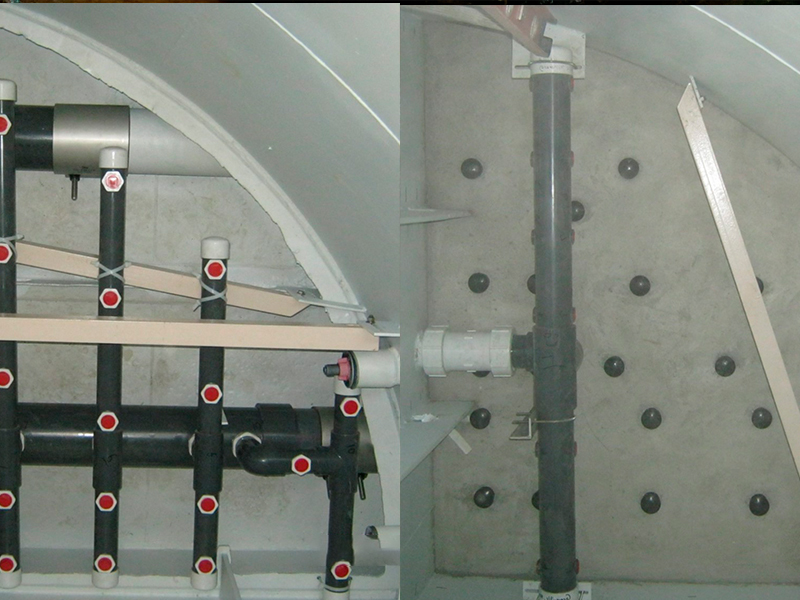

When changing out media, Kurita America also recommends replacing support gravels and other buried components like air scour grids and retaining nozzles (see Figures 2 & 3). Replacing these items ensures that the filter is in its best possible condition following the refurbishment, and the additional cost is generally small compared to base costs associated with the media and contractor labor. It also offers a rare glimpse of the filter’s interior for inspection purposes.

Depending on the type and age of the filter, additional scope considerations are justified. For steel tank filters older than 20 years, blasting and painting of internal surfaces may be warranted to maintain material integrity and ensure the longest additional equipment life. Some false bottom, steel plate underdrains are susceptible to corrosion and subsequent failure, which can be unpredictable. These can be replaced with PVC header-lateral systems to eliminate concerns of failure and prevent costly emergencies (see Figure 4). Concrete basin filters may require underdrain replacement too, depending on the type of underdrain and its expected life.

There are inherent unknowns when considering whether to replace an underdrain. Access below the underdrain is often limited or not available, and the underdrain itself is buried by filter media. This complicates the direct inspection of an underdrain, so the decision to replace is often driven by indirect observations and equipment age. An uneven media surface immediately following backwash (visible craters or mounds) would indicate that the underdrain is compromised as would discovering media grains below the underdrain or in the finished water. Even without any indirect signs of failure, age alone might justify replacing an underdrain on a proactive basis to prevent a future emergency. Because underdrain replacement adds considerable cost to a refurbishment project in both parts and labor, the decision is sometimes left until after an inspection once the media and other internals are removed. This can help avoid any unnecessary expenses. Though, deciding to replace the underdrain at that point will likely mean project delays and additional costs as compared to those expected if planning to replace the underdrain from the beginning.

There are many possible approaches when considering a filter refurbishment as part of your asset management plan. The simplest approach is to plan on full replacement of filter media and internals (excluding the underdrain) at or around 15 years. The exact timing should be advised by periodic assessments of condition and performance. When the media is to be replaced, consider additional scope if the age of the filter is approaching or greater than 20 years.

The best maintenance strategy will depend on your specific filter application. Kurita America is here to help you navigate the available options to understand the potential benefits in light of the associated costs. Contact Kurita America’s Aftermarket Services Department to start the conversation with a media filtration expert.

About the Author: T.J. Stroebl is a technical marketing leader at Kurita America, specializing in equipment systems. After earning a chemical engineering degree from the University of Minnesota, he has spent his career with Kurita America focusing on process and equipment design, troubleshooting, and development relevant to water treatment systems. T.J. is an active member of the American Water Works Association (AWWA), currently serving on their Board of Directors as Chair of the Manufacturers/Associates Council (MAC).

About the Author: T.J. Stroebl is a technical marketing leader at Kurita America, specializing in equipment systems. After earning a chemical engineering degree from the University of Minnesota, he has spent his career with Kurita America focusing on process and equipment design, troubleshooting, and development relevant to water treatment systems. T.J. is an active member of the American Water Works Association (AWWA), currently serving on their Board of Directors as Chair of the Manufacturers/Associates Council (MAC).

Figure 1: Example of media growth and mud-balling due to build-up of solids.

Figure 1: Example of media growth and mud-balling due to build-up of solids.  Figure 2: Horizontal pressure filter arched-plate underdrain with new nozzles following blasting and painting of internal steel surfaces.

Figure 2: Horizontal pressure filter arched-plate underdrain with new nozzles following blasting and painting of internal steel surfaces.  Figure 3: Horizontal pressure filter shown with new graded gravels and air scour grid, prior to placement of filter media.

Figure 3: Horizontal pressure filter shown with new graded gravels and air scour grid, prior to placement of filter media.  Figure 4: Retrofit of steel plate underdrain system with header-lateral type, before (left) and after (right) the addition of concrete sub-fill.

Figure 4: Retrofit of steel plate underdrain system with header-lateral type, before (left) and after (right) the addition of concrete sub-fill.