Filtration

Kurita offers a variety of filtration options to remove precipitated or suspended solids from water sources. Our filtration systems are used to treat raw surface water or groundwater for use as industrial process water or municipal drinking water. They also provide additional pre-treatment for utility water, like cooling tower makeup and boiler feed water, or higher purity needs. Filtration prevents fouling and solids buildup in your water systems and equipment assets, allowing them to run smoothly and reliably for longer durations. Our systems include PLC-driven control panels for fully automated operation in service and cleaning modes.

- Utility water pre-treatment (i.e. cooling water, boiler feed)

- Cooling tower side-stream filtration

- High purity or ultrapure water (UPW)

- Raw water treatment (surface water, groundwater)

- Municipal drinking water

- Tertiary wastewater treatment

- Water reuse

- Biological Filters: Media filters can be operated biologically to treat common groundwater contaminants, like iron, manganese, and ammonia, without chemical oxidants. Benefits of biological treatment often include reduced chemical consumption, increased filter run lengths, and greater finished water stability for ease of disinfection. Contact us to learn how your application might benefit from biological filtration.

- Gravity Filters: Gravity filtration allows for smooth flow with minimal disturbance of formed solids, which can be sheared through mechanical pumps and turbulent flow. Operators enjoy ease of access, whether for observation during treatment or maintenance while out of service. Kurita America’s line of gravity filter products and features provide a range of design possibilities:

- Centralator™: center control column 4-cell cluster filter

- Filtralator™: steel or aluminum fabricated multi-cell filter

- Dualator™ Series: packaged groundwater treatment systems

- UTS™: packaged conventional treatment system

- BLEU™: stainless steel underdrain system

- Uni-Cast™ II: monolithic underdrain system

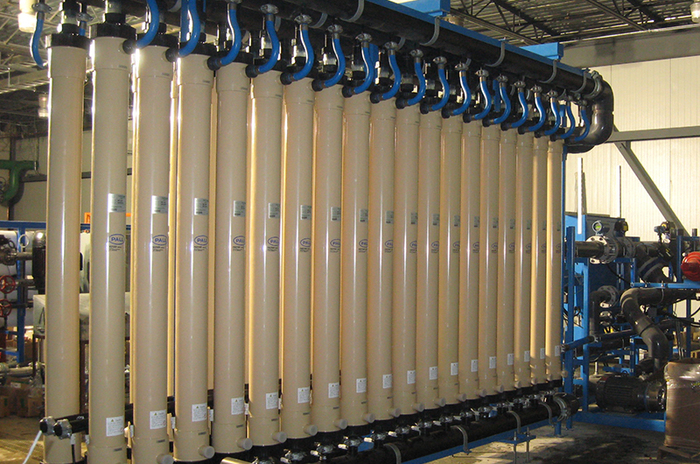

- Pressure Filters: Pressure filters are implemented into a pressurized flow stream, allowing for continuous treatment from source to finish without additional stages of pumping. The forced flow can overcome greater head-loss to accommodate more solids loading and higher-rate applications to optimize operation and equipment sizing. Our pressure filter systems are customizable and include options for underdrain type, multi-cell configuration, and skid mounting. Kurita America’s pressure filter product line includes the following equipment and features:

- VertaCell™ vertical pressure filters

- OptaCell™ horizontal pressure filters

- OptaCell™ Plus isolated cell configuration

- Simul-Wash: Kurita’s Simul-Wash is an advanced backwashing technology that provides optimal cleaning of media filters while minimizing water waste. Learn more about Simul-Wash or contact us to find out how it can benefit your media filtration application.

- Dualator® Series

- Unitized Treatment System (UTS®)

- Aerators, degasifiers, and stripping towers

- Chemical feed systems

- Clarification systems

- Flocculation and sedimentation equipment

- Cartridge filters

- Filter housings

- Filter media

- Strainers

- Chemical feed systems

- Media filters

- GAC filters

- Point-of-use filters

- RO/NF membrane systems

- Controllers