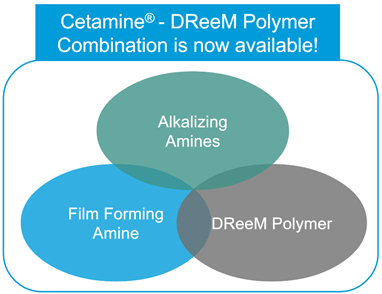

Cetamine DR combines two unique chemistries to create a one-drum product to better serve you, your facilities, and your boilers. Kurita’s Cetamine and DReeM Polymer™ technologies work together to offer big benefits in low-pressure boiler applications by combining complete corrosion protection with deposit control as well as online deposit removal in scaled boilers.

Cetamine has a long history of treating boilers, cooling towers, and closed loops to provide complete protection. Composed of film-forming amines, Cetamine creates a hydrophobic protective film that absorbs on all metal surfaces in the system. Unlike traditional chemical programs that treat the water for impurities, this film creates a continuous barrier between the water and metal, effectively inhibiting corrosion without affecting the heat transfer. The film is especially beneficial in condensate systems plagued with dissolved oxygen corrosion or flow accelerated corrosion, conditions where traditional neutralizing amines are not effective. Cetamine products are available as single drum film-forming amine blends and formulated for different types of water make-up qualities, industries, and applications.

Cetamine has a long history of treating boilers, cooling towers, and closed loops to provide complete protection. Composed of film-forming amines, Cetamine creates a hydrophobic protective film that absorbs on all metal surfaces in the system. Unlike traditional chemical programs that treat the water for impurities, this film creates a continuous barrier between the water and metal, effectively inhibiting corrosion without affecting the heat transfer. The film is especially beneficial in condensate systems plagued with dissolved oxygen corrosion or flow accelerated corrosion, conditions where traditional neutralizing amines are not effective. Cetamine products are available as single drum film-forming amine blends and formulated for different types of water make-up qualities, industries, and applications.

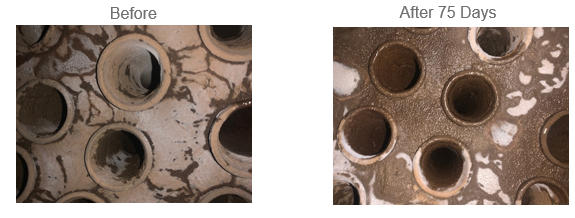

DReeM Polymer is Kurita’s award-winning polymer technology that removes silica and hardness scale from boiler surfaces up to four (4) times more efficiently than conventional polymers. Silica is one of the most insulating scale deposits and hardest to remove once formed. Some areas, like the southwestern United States, have very high levels of silica in the makeup water, which makes it difficult to treat. Kurita's DReeM Polymer, which stands for Dispersion and Removal effect Management, disperses impurities in the boiler water and removes existing deposits from the boiler tubes. This unique chemistry has the effectiveness of traditional chelants that are commonly used for online cleaning of hardness scale but without the corrosion concerns.

DReeM Polymer is Kurita’s award-winning polymer technology that removes silica and hardness scale from boiler surfaces up to four (4) times more efficiently than conventional polymers. Silica is one of the most insulating scale deposits and hardest to remove once formed. Some areas, like the southwestern United States, have very high levels of silica in the makeup water, which makes it difficult to treat. Kurita's DReeM Polymer, which stands for Dispersion and Removal effect Management, disperses impurities in the boiler water and removes existing deposits from the boiler tubes. This unique chemistry has the effectiveness of traditional chelants that are commonly used for online cleaning of hardness scale but without the corrosion concerns.

The Cetamine DR product line combines the corrosion protection of Cetamine technology with the DReeM Polymer for superior boiler scale control. By taking two novel technologies, Kurita America offers the best of both worlds for corrosion and scale control. This is a one-drum approach, compared to a multi-drum approach of separate products with individual pumps and onsite tanks. This boiler product approach further expands on the Cetamine product line by dramatically increasing the scale prevention capability, simplifying application, and offering a unique solution for complete boiler system protection.

The Cetamine DR product line combines the corrosion protection of Cetamine technology with the DReeM Polymer for superior boiler scale control. By taking two novel technologies, Kurita America offers the best of both worlds for corrosion and scale control. This is a one-drum approach, compared to a multi-drum approach of separate products with individual pumps and onsite tanks. This boiler product approach further expands on the Cetamine product line by dramatically increasing the scale prevention capability, simplifying application, and offering a unique solution for complete boiler system protection.

Customers operating on a Cetamine, DReeM Polymer standalone, or traditional boiler treatment program can benefit from this new chemistry by combining the advantages of each technology. Studies from systems that have switched from traditional treatments to Cetamine have shown lower boiler water conductivity, subsequently allowing for higher cycles of concentration that reduces blowdown and water, energy, and chemical costs. Adding the DReeM Polymer for scale dispersion and removal, the combination of the two can yield significant operational savings for fouled and challenged boiler systems.

Cetamine DR provides online removal of the most difficult deposits without the use of traditional chelants or offline acid cleanings that can promote corrosion in the boiler. The direct impact of cleaner boiler tubes is fuel cost savings, which even at 0.5-5% reduction can add up to significant values. One study from a customer using DReeM Polymer showed an estimated reduction in fuel of 13.1% with an annual total cost of operation savings of $10,000. With over 5,000 Cetamine boiler applications globally, multiple studies support the benefits and savings achieved with that unique technology as well. Now available together in a convenient one drum product line, Cetamine DR can reduce fuel costs and facility CO2 emissions and provide overall operational savings, asset preservation, and increased plant reliability.

Kurita’s Cetamine and DReeM Polymer technologies work together for big benefits in low-pressure boiler applications. Together, they are a groundbreaking treatment to reduce costs for the customer while conserving natural resources for a better, more sustainable world.

Contact Kurita America to learn if Cetamine DR will work for you.

Cetamine® DR: Merging Cetamine and DReeM Technologies for Exceptional Results