EnergyOUT™

An Integrated Water Solution for Boilers

Plants are often looking to increase their steam boiler efficiency but do not have a sufficient capital budget for a new reverse osmosis (RO) system. Kurita's fully integrated EnergyOUT solution meets this need.Available through an operating lease, EnergyOUT includes equipment, standard service, chemicals, and consumables for a set, monthly price.

EnergyOUT Customizable Platform

EnergyOUT's RO technology removes dissolved ions in boiler feedwater, resulting in enhanced plant sustainability by lowering fuel demand, carbon emissions, chemical use, and water discharge. Once installed, Kurita representatives train facility personnel on system operation and limited maintenance. Learn more about our customizable options:

- A complete RO sized correctly for your system, available in 7.5, 15, 30 and 50 gallons per minute

- Carbon filtration and pre-filters to protect the RO membranes

- RO product water storage tank with level controls

- RO product water forwarding pump

- pH adjustment of the RO permeate to prevent corrosion

- RO is built with a VFD controlled pump and low energy membranes to reduce electric consumption

- EnergyOUT skids are pre-built and ready to install, greatly reducing installation time

- Available in three or five year contracts with the option to re-sign

- Remote system monitoring

EnergyOUT Benefits

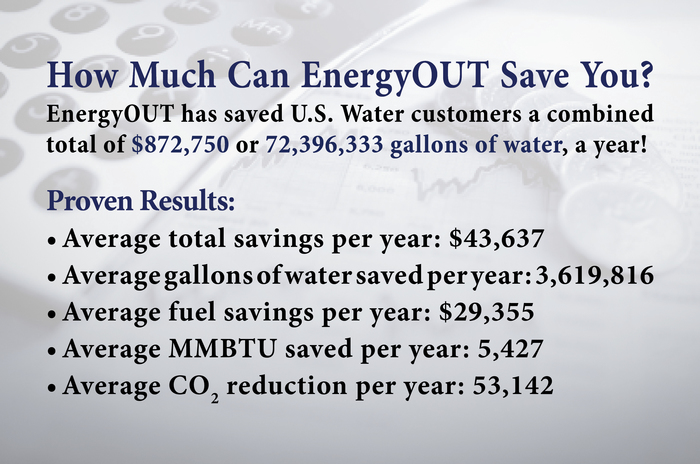

Because of its integrated nature, Kurita’s technology controls the demand for treatment of chemicals and water. It works to keep heat transfer surfaces clean in boilers, ultimately reducing fuel consumption and produced CO2 emissions.

Kurita’s EnergyOUT program lowers a facility’s freshwater demand, energy utilization, chemical consumption, and carbon footprint. As many companies seek to lower their environmental impact and promote sustainability, EnergyOUT is an easy first step toward reaching these goals.

With steam boilers using RO permeate as makeup water, the risk of solids carryover from the boiler system into the steam distribution piping is greatly decreased. Combined with the additional benefits of lower chemical consumption and increased boiler water quality, the EnergyOUT program increases steam purity throughout the plant.

Standard with the EnergyOUT program, all routine maintenance and repairs are included. This means no unexpected costly repair expenses to limited maintenance staff availability or trouble locating needed parts. Our regular field visits and annual system audits provide peace of mind.