A thin layer of scale can reduce heat transfer efficiency by up to 10%, increasing fuel consumption and the produced greenhouse gas emissions. Descaling a boiler and implementing a regular boiler treatment program will help keep the boiler system running, but you should take it a step back, starting with the water supplying the boiler. Boiler feedwater is as important as the water in the boiler itself, so it may be time to upgrade to a more modern treatment process, such as reverse osmosis (RO) membranes.

The Role of Boiler Feedwater

Boiler feedwater plays a critical role in the production of steam and the overall efficiency of a boiler system because it is treated water supplied to a boiler for steam generation. Whereas boiler water refers only to the water and ultimately the steam inside the boiler during operation, feedwater is treated before entering the boiler system.

Boiler feedwater is comprised of two very important and increasingly expensive resources:

- Steam condensate return, which is recovered and cycles high temperature, high quality water back into the boiler feedwater system.

- City (or well) makeup water to replace water lost during operation.

The condensate is valuable due to its low electrical conductance, purity, and high temperature, while the makeup water is increasingly costly due to overuse and limited availability in many regions. This combination forms the feedwater loop, which ensures a continuous and stable water supply to the boiler.

Feedwater Quality Matters

The primary goal of feedwater treatment is to inhibit impurities that cause scale, corrosion, foaming, or inefficient heat transfer, so managing feedwater quality effectively is essential for stabilizing fuel consumption and extending the life of boiler equipment.

Impurities like hardness, silica, and dissolved solids can damage boiler tubes, pumps, and heat exchangers, leading to increased maintenance costs and unplanned downtime. Plants can ensure effective boiler water treatment by maintaining the right chemical balance and controlling dissolved solids. High-quality feedwater directly contributes to lower operational costs and improved overall reliability of the steam system. This is why upgrading feedwater pre-treatment is important to retain quality and protect assets.

Traditional vs. Modern Feedwater Treatment Approaches

Historically, when facilities sought to improve the quality of boiler feedwater, the options were limited: either soften or demineralize the makeup water or increase the condensate return. While these can effectively reduce hardness and remove certain impurities, they sometimes fall short when it comes to minimizing dissolved solids, silica, and organics to the level required for today’s high-pressure boilers.

In recent years, advancements in RO technology have made it a reliable and cost-effective solution for producing high-quality feedwater. The use of RO in boiler water pre-treatment can make sense for many boiler installations to meet increasingly stringent water quality standards and improve system efficiency.

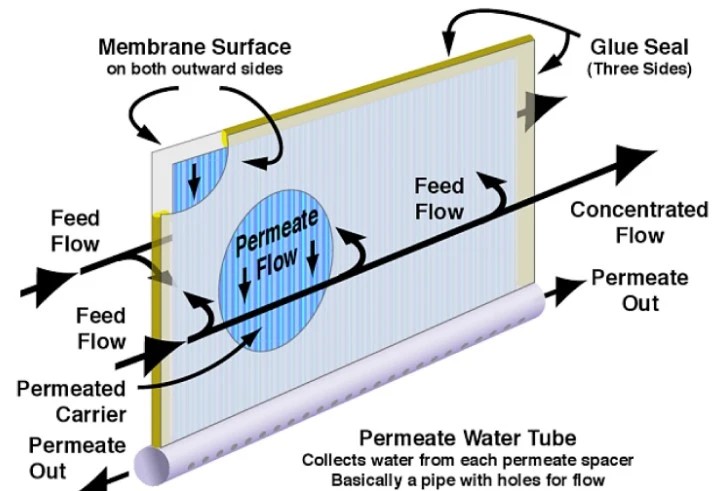

RO uses semi-permeable membranes to remove over 98% of dissolved solids, providing consistent water quality, reduced chemical consumption, and improved efficiency and safety of boiler operations.

The Advantages of Reverse Osmosis in Boiler Feedwater Treatment

Most people will know reverse osmosis for its high-purity standards in both residential and industrial settings, RO makes that extra quality step from city water into operational boiler feedwater. While reverse osmosis units may seem like a luxury in some cases, they remove a variety of contaminants while improving boiler and steam quality by producing highly purified water.

Incorporating an RO system can have potential drawbacks, such as the initial capital expense, cleaning and replacing the RO membranes, and even added energy use involved in pumping RO feedwater. However, facilities could see the following savings annually by the incorporating an RO system:

- Reduced chemical consumption by 50 to 60%

- Reduced boiler blowdown by 4 to 5%

- Reduced fuel costs by 3 to 4%

Just those reductions can be potentially thousands of dollars in savings. Besides the economic benefits, there are operational advantages to using RO technology in boiler feedwater treatment:

- Increased in boiler cycles of concentration – as much as 80 to 100 cycles – resulting in reduced blowdown and heat loss

- Reduced makeup water usage

- Minimized boiler deposits to increase boiler efficiency

- Reduced feedwater alkalinity with the direct result of lower neutralizing amine use

- Improved cleanliness of heat transfer surfaces

Additionally, if a cation exchange softener is used ahead of the RO unit, the concentrate output from the RO may be high enough quality to use as makeup for an evaporative cooling tower system or other process water systems.

Although RO systems require initial capital investment and ongoing maintenance, these costs are typically offset by long-term efficiency gains and reduced operating expenses.

Key Considerations Before Implementing Reverse Osmosis

Due to the variety of membrane units, your makeup water supply, and even process and facility size, there should be an in-depth analysis completed to determine if an RO unit would best work for you. Here are several factors to be assessed:

- Steam pressure and boiler type: higher pressures require higher feedwater quality

- Makeup water quality: higher levels of dissolved solids can increase fuel, water and chemical consumption, increasing the benefit of RO for makeup

- Variable steam loading: RO works more effectively at steady-state flow rates

- Condensate return: high quality, high-volume return may reduce the need for extensive treatment

- Pre-treatment requirements: feedwater may require softening or dechlorination prior to RO

- A comprehensive water analysis and system evaluation can help determine whether RO will deliver the expected performance benefits and cost savings.

Sustainability and Efficiency Gains

RO technology not only enhances boiler efficiency but also supports sustainable water management practices. By reducing blowdown volume, chemical use, and fuel consumption, RO systems help lower a facility’s environmental footprint. They minimize the need for freshwater intake and decrease wastewater discharge, aligning with responsible water stewardship goals.

The ability to reuse RO reject water for auxiliary systems, such as cooling towers, further contributes to conservation efforts and cost savings.

Conclusion

The operation and maintenance of a boiler system is one of the most expensive and labor-intensive activity in facilities. Reverse osmosis has proven to be one of the most effective technologies for improving feedwater quality, reducing operational costs, and ensuring reliable steam production.

By integrating RO into feedwater treatment systems, operators can achieve long-term efficiency, better control over water quality, and meaningful progress toward sustainable operations.

Contact Kurita to optimize your boiler feedwater and increase your steam condensation.