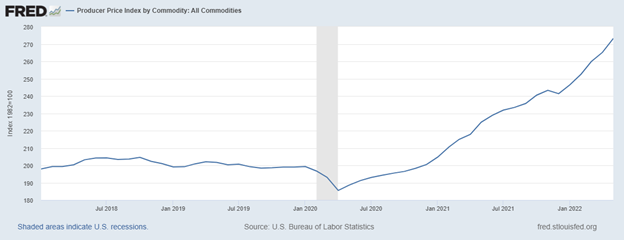

The consumer price index (CPI) for all commodities increased by approximately 50% between March 2020 and March 2022 (Figure 1) with the primary contributor being global supply chain disruptions due to COVID-19. Many companies were not getting the raw materials or finished goods needed for their specific business or their consumer needs. Organizations that waited to make changes are experiencing compounded supply chain challenges, while those who recognized and implemented changes to adapt have mitigated those risks. With a focus on customer needs, Kurita America took steps to improve our supply chain management with an eye toward logistics to provide our customers with better and shared value options.

Figure 1, courtesy of the Federal Reserve Bank of St. Louis

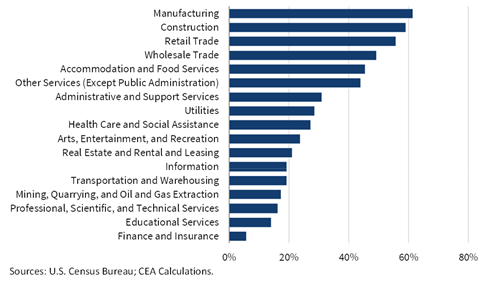

It is rare to find a company that has not been affected by supply chain disruptions, especially with the globalization of business. Locally sourced, produced, and shipped products are the exception — not the rule — and depending on the complexity or availability of the product, you may have a product sold in the United States that has components from over 30 different countries with 30 supply chains, affecting the cost and availability of finished goods. Globalization in general has been a positive trend. Technology has evolved and processes improved due to expanded business relationships, innovation, and the exchange of ideas. This also helped create an economic model that allowed organizations to cost effectively source raw materials and labor. Unfortunately, that economic model is strained. COVID-19 and geopolitical stressors have reduced the global labor supply, slowed infrastructure investment, and crowded shipment ports, further reducing supply chain options. Aging manufacturing facilities running at full capacity are one weather event, COVID-19 shutdown, or equipment failure away from falling behind their demand curve, adding additional stress to the supply chain. Additionally, companies are experiencing a labor shortage. According to the U.S. Bureau of Labor and Statistics, at the peak of the pandemic in the United States, 16.9 million Americans were unemployed with 57 percent of those people unable to work “because their employer closed or lost business due to the pandemic.” Figure 2 from the White House is from June 2021, showcasing supply chain disruptions per sector.

The labor challenges directly impact the global supply chain by interrupting raw material shipments, production schedules, and logistics schedules. Peter Sundra, head of the global logistics at Visy Industries was interviewed by Reuters, saying, “‘We believe the current congestions, not only the ports but also the landside infrastructure, will be there at least till Q1 2023.’” Based on these challenges, Kurita America has adapted to the new norm.

Even before the pandemic, Kurita America was working with our national and global business partners as the international Kurita acquisitioned American-based companies. Our most recent efforts have focused on uniting the best products of several companies to meet customer needs, improving internal processes, mitigating supply chain issues, and adapting to the changing supply chain by implementing the following.

- Creating a select and non-select category of products.

By evaluating customer product mix, Kurita America has been able to both ensure product availability and shorten lead times. - Consolidating and optimizing product lines.

Kurita America allows our operations and purchasing teams to manage stocking levels and the distribution of products efficiently and effectively, which minimizes the impact on customers. - Establishing daily, weekly, and monthly cadence calls between Operations, Procurement, Product Management, and Sales teams.

Kurita America addresses immediate concerns regarding supply chain and continues to improve the existing processes to meet customer needs. - Improving vendor communication has allowed Kurita America to identify critical raw material and finished good gaps.

By ensuring Kurita America addresses these issues early in the sales/supply chain process, we meet production and customer needs.

Figure 3, product consolidation over time

The strategic category of products and the consolidation down to 700 products lets Kurita America better serve customers with their chemical and equipment needs for their toughest challenges and planned shipments. Companies and regular people are facing steep inflation, Kurita America too. With this, Kurita America can reduce passing costs onto our customers. It may not be immediate, but over time, the prices will fall back into normal margins. Kurita America has adapted our business model to increase organizational speed in responding to the uncertainty in the market. Additionally, introducing the concept of Creating Shared Value (CSV) during this market uncertainty is providing customers with additional resources and answers in improving their bottom line and achieving sustainability initiatives.

Kurita America is committed to promoting lasting change in everything we do and incorporates conservation into our research and development as well as our solutions. We have adapted processes to meet the changing global economy, and by providing the CSV technologies (shown below), Kurita America helps customers decrease their dependency on an already-stressed supply chain. Kurita America has introduced products that create shared value:

- Boiler

- Cooling

- Cooling Tower Blowdown Recovery (CTBR)

- Cetamine®

- Reverse Osmosis (RO)

- Kuriveriter® IK-110

- Avista Global Product Line (GPL)

- Liquid-Solids Separation (LSS)

These products were designed to be the best application or technical fit for our customers to increase efficiencies, decrease downtime, and improve a facilities water management program. An unintended benefit of these offerings was their timeliness. The CSV products gave Kurita America another way to decrease customer dependency on supply chain. By providing alternative solutions and new technologies that were more easily sourced and produced, we decreased some of those supply chain hurdles, meeting customers water treatment and management requirements. A global economy and a global pandemic have created a fundamental shift in the way we do business. Supply chain challenges will continue to negatively impact even the most well-run organizations. Partnerships with trusted and innovative business partners, who adapt quickly and introduce new technologies, are key considerations as organizations look to grow their market share. Ultimately, reducing those 1,400 products to less than 700 products and providing shared value technology continues to meet our customers’ needs.

Kurita America’s improved supply chain management and introduction of shared value technologies is benefitting their business partners. Kurita America will continue to deliver products, technologies, and services that help customers. Together, Kurita America and our customers will increase operational efficiencies, reduce CO2 emissions and waste, improve water management, and create a better, more sustainable world.

References

Helper, S. and Evan Soltas. (2021, June 17). “Why the Pandemic Has Disrupted Supply Chains.” The White House. https://www.whitehouse.gov/cea/written-materials/2021/06/17/why-the-pandemic-has-disrupted-supply-chains/

Lerh, J. (2022, June 15). “Global Port Congestion, High Shipping Rates to Last into 2023 – Execs.” Reuters. https://www.reuters.com/business/global-port-congestion-high-shipping-rates-last-into-2023-execs-2022-06-16/

“Producer Price Index by Commodity: All Commodities.” (N.A.) Federal Reserve Bank of St. Louis. https://fred.stlouisfed.org/series/PPIACO

“Supplemental Data Measuring the Effects of the Coronavirus (COVID-19) Pandemic on the Labor Market.” (N.A.) U.S. Bureau of Labor Statics. https://www.bls.gov/cps/effects-of-the-coronavirus-covid-19-pandemic.htm